From design to production

Innovate with us.

We are the forefront of maritime innovations

A premier naval technology firm, enabling new asymmetric strategies so US Navy and military forces can prevail over the next several decades in multi-dimensional conflicts. MAPC brings a significant track record supporting relevant U.S. Government and commercial customers and a deep bench of hardware and software technical expertise to the BlackSea platform. As the U.S. Government continues to increase its support of innovative littoral platforms, BlackSea is well positioned to build off past success and support for customers within the evolving national security space.

Breaking product barriers that define industry standards

Maritime Applied Physics Corporation (MAPC) specializes in the design and production of advanced technology systems and innovative, ruggedized platforms suited to withstand the harshest maritime environments.

Let’s conquer the opportunity

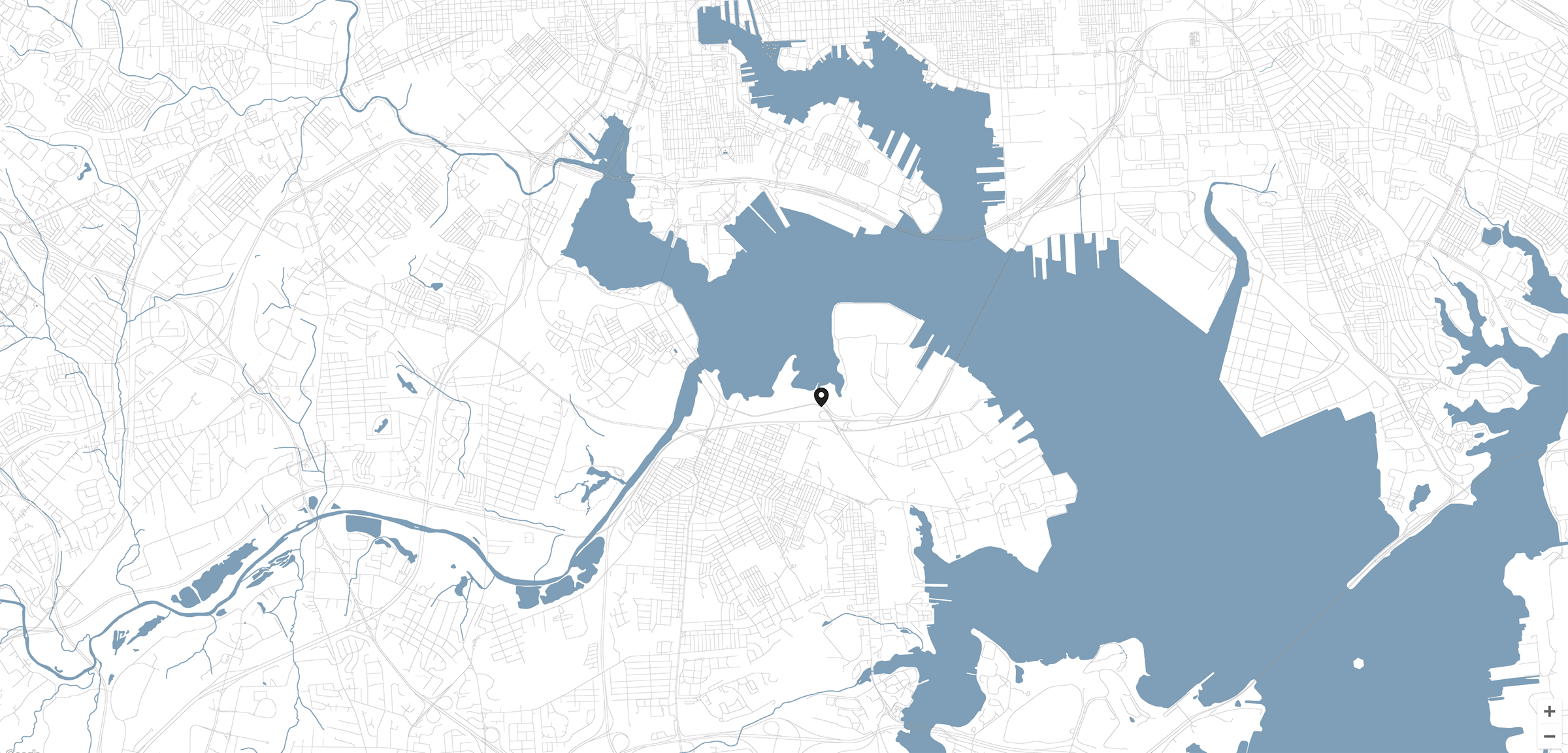

MAPC’s headquarters location was once a Liberty Ship shipyard, with 384 Liberty ships, 94 Victory ships, and 45 LSTs built by 47,000 workers between 1941 and 1945. Across the water is Fort McHenry, the site of the battle that inspired Francis Scott Key to write our National Anthem during the War of 1812. On these historic grounds, MAPC is mission-focused on what comes next.

MAPC Baltimore

1850 Frankfurst Avenue

Baltimore, Maryland, USA 21226-1024

Phone: (+1) 443-524-3330 x 134

Contact: Elizabeth Hines, Manager, Business Development

Email: ehines@mapcorp.com

MAPC Maine

9 Industrial Parkway, Suite 4

Brunswick, Maine, USA 04011-7315

Phone: (+1) 207-837-6175, ext. 203